Eighth-grade student Elliot Irving loves to yo-yo. This past summer Elliot took the hobby a step further and decided to design his very own unresponsive yo-yo. “[It’s] a yo-yo meant for tricks,” says Elliot, “and it doesn’t come up when you tug on it. It requires a bind to come up.”

On a road trip from San Francisco to Washington, Elliot’s family took a detour and stopped in Eugene, Oregon, to visit a yo-yo company called One Drop.

“I got a tour of their manufacturing facility and they explained how all the machines worked and what the process was. When I told them that I had designed my own yo-yo, they were thrilled. They helped me make some tweaks, such as widening areas, replacing bearing seats, etc. It was awesome.”

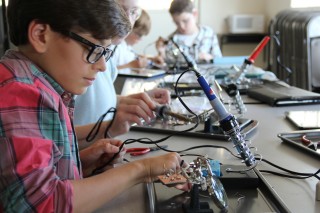

As soon as Elliott found out there was a 3D printer at school he had a project in mind. “I was so excited and the first thing that popped into my head was to prototype the yo-yo.” Elliot has been spending his lunchtime in the school’s brand new design lab with his Design Tech teacher Barbara Abecassis to design and engineer his own yo-yo. “He built it in 3D Cad,” says Abecassis, “and we used the 3D printer to test it as a prototype.”

When asked about the toy he designed, Elliott says, “it is usable, but very limited to tricks. It can spin for about 9 seconds and it is responsive because of the slightly abrasive plastic. I am really happy with the shape I designed as I had no idea what it would feel like in hand. The next step is to machine it out of aluminum!”